Operation manual of belt drum packing machine

Machine model: xq-500-a

Equipment explanation

Xq-500-a drum type packaging machine is a kind of equipment for all kinds of tape packaging. It adopts the packaging process of flow line feeding, automatic separation, automatic feeding, automatic sealing and cutting, and automatic heat shrinkable molding. The equipment is easy to operate, stable, energy-saving, and efficient. The packaging products are beautiful. In the case of higher and higher customer requirements for packaging, it can save a lot of labor costs for tape production, And the improvement of packaging quality, make the market competition more advantage

Equipment parameters

Effective width of cutter: 500mm

Width of finished product: 250-350mm

Packaging product diameter: 80-140mm

Packaging film material: PVC heat shrinkable film (1.8-2 filament thickness, longitudinal shrinkage 40%, transverse shrinkage 10%)

Packaging film mother coil: the maximum diameter is 250mm (within 15kg)

Production speed: 18 drums / min

Air source: 5kg

Power supply: packaging machine: 220 V single-phase power supply 400 W heat shrinkable machine: 380 V three-phase power supply 11 kw

Equipment configuration

|

Name |

Specifications |

Nnumber |

Brand |

Remarks |

|

Interface |

TPC 7062HI |

1PCS |

Kunlun state |

|

|

Power switch |

Three phase 32A |

1PCS |

Keneda |

|

|

Circuit breaker |

2P25A |

1PCS |

Admiralty mill |

|

|

Program controller |

CF-28MT |

1PCS |

San Jie Li |

|

|

relay |

MY2NJ-24VDC |

3PCS |

Schneider |

|

|

Power supply |

LRS-50-24 |

1PCS |

Mingwei |

|

|

Power supply |

LRS-350 |

1PCS |

Mingwei |

|

|

Solid state relay |

SSR-30DD |

1PCS |

欣大 |

|

|

Contactor |

LC1-N0910 |

1PCS |

Schneider |

|

|

Emergency stop switch |

22MM |

1PCS |

Schneider |

|

|

Start button |

22MM green |

2PCS |

Schneider |

|

|

Stop button |

22MM gules |

1PCS |

Schneider |

|

|

Indicator light |

22MM gules |

1PCS |

Schneider |

|

|

Buzzer |

22MM gules |

1PCS |

Schneider |

|

|

Upper / lower membrane sensor |

JF-1805N |

2PCS |

LANDWELL |

|

|

Incoming material sensor |

JY-1205N |

1PCS |

LANDWELL |

|

|

Pusher sensor |

JF-01 |

1PCS |

Yadeke |

|

|

Pressure sensor |

CS-1 |

1PCS |

Yadeke |

|

|

Assembly line motor |

200W/10 |

1PCS |

Meili |

|

|

Upper / lower membrane motor |

25W-25/1 |

2PCS |

Meili |

|

|

filter |

SCF-2000 |

1PCS |

Xin Gong |

|

|

Solenoid valve |

TG2521-DC24V |

4PCS |

天工 |

|

|

Pushing cylinder |

TN-32-275-S |

1PCS |

Yadeke |

|

|

Disengaging the cylinder |

TN-25-30 |

1PCS |

Yadeke |

|

|

Stop cylinder |

TN-16-10 |

1PCS |

Yadeke |

|

|

Beating cylinder |

TN-16-30 |

2PCS |

Yadeke |

|

|

Press cylinder |

TN-25-100 |

1PCS |

Yadeke |

|

Production process

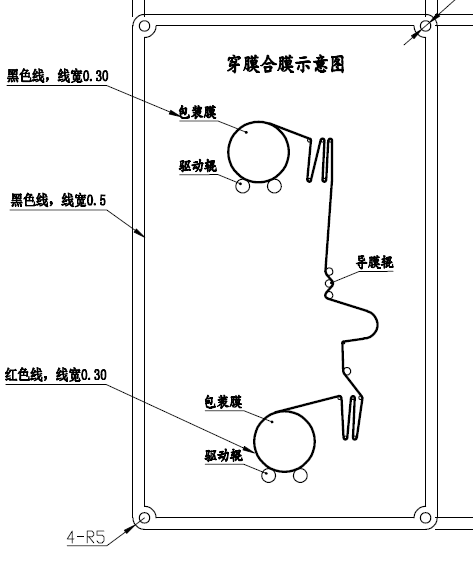

The belt is arranged on the production line - automatic start - belt in place induction - pressing and pulling off - pushing - back pressing and positioning - sealing and cutting molding - entering the heat shrinkable machine for molding - finished product completion

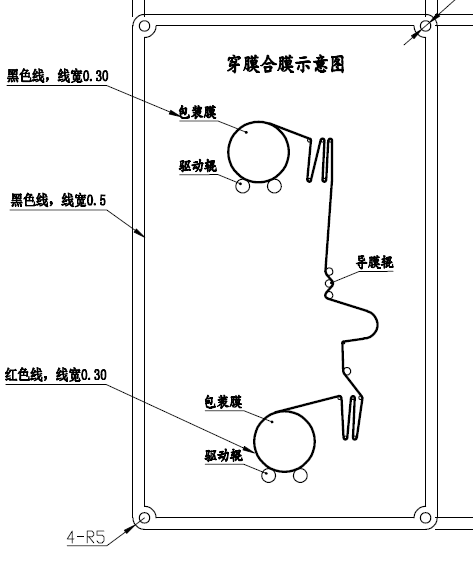

Note: after putting on the membrane, please select the manual mode in the man-machine, enter the manual operation page, press the cutter to seal and cut the upper and lower membrane

Belt feeding adjustment

1: Adjust the assembly line to the right position according to the diameter of the tape

2: The length and width of the cylinder can be adjusted according to the quantity of the packing tape

3: The length of the pushing plate and the packing tape can be adjusted (the length of the information plate can be adjusted)

4: The baffle plate is positioned according to the length of the packing tape. Adjust the screw handle

Note: the length of the finished product is adjusted by the baffle positioning and pushing into the plate

Because the adhesive between the tape and the tape is too strong, it is necessary to pull away the adhesive between the two tapes, so it is very important to pull away the tape. It is necessary to separate the material according to the packaging length of the tape, so as to push the material more smoothly

Discharge device

Discharge device: press cylinder, left and right beating cylinder to arrange the tape in order

1: According to the diameter of the belt, turn the pressure plate to the screw handle and set it in the right position

2: When the air cylinder is extended, adjust the edge of the belt and leave a 2mm gap. The purpose of this device is to prevent the separation of the belt

Operating instructions

1: Turn on the power switch and power on the equipment.

2: There are Chinese version and English version for man-machine operation

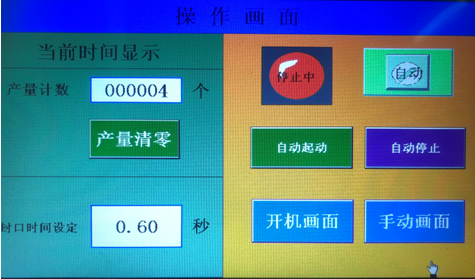

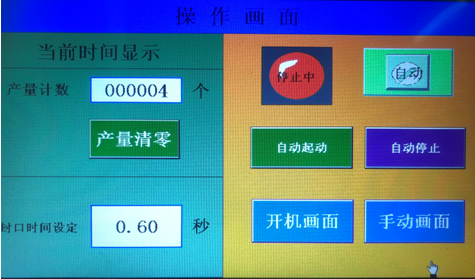

3: Output count, can count production output, can clear

4: Sealing time setting: it refers to the time of sealing and cutting. When leaving the factory, the time has been adjusted after testing. It is suggested that the normal time is 0.6-0.7 seconds. If the sealing is not good, it can be changed

5: Alarm reset button, if the machine gives a fault alarm, after troubleshooting, press this button to clear reset

6: Automatic / manual mode: automatic mode (the default mode for startup), press the auto start, and the machine will run automatically

Automatic start in the table, and the operation panel, there is a button, and the man-machine start function, can start the machine

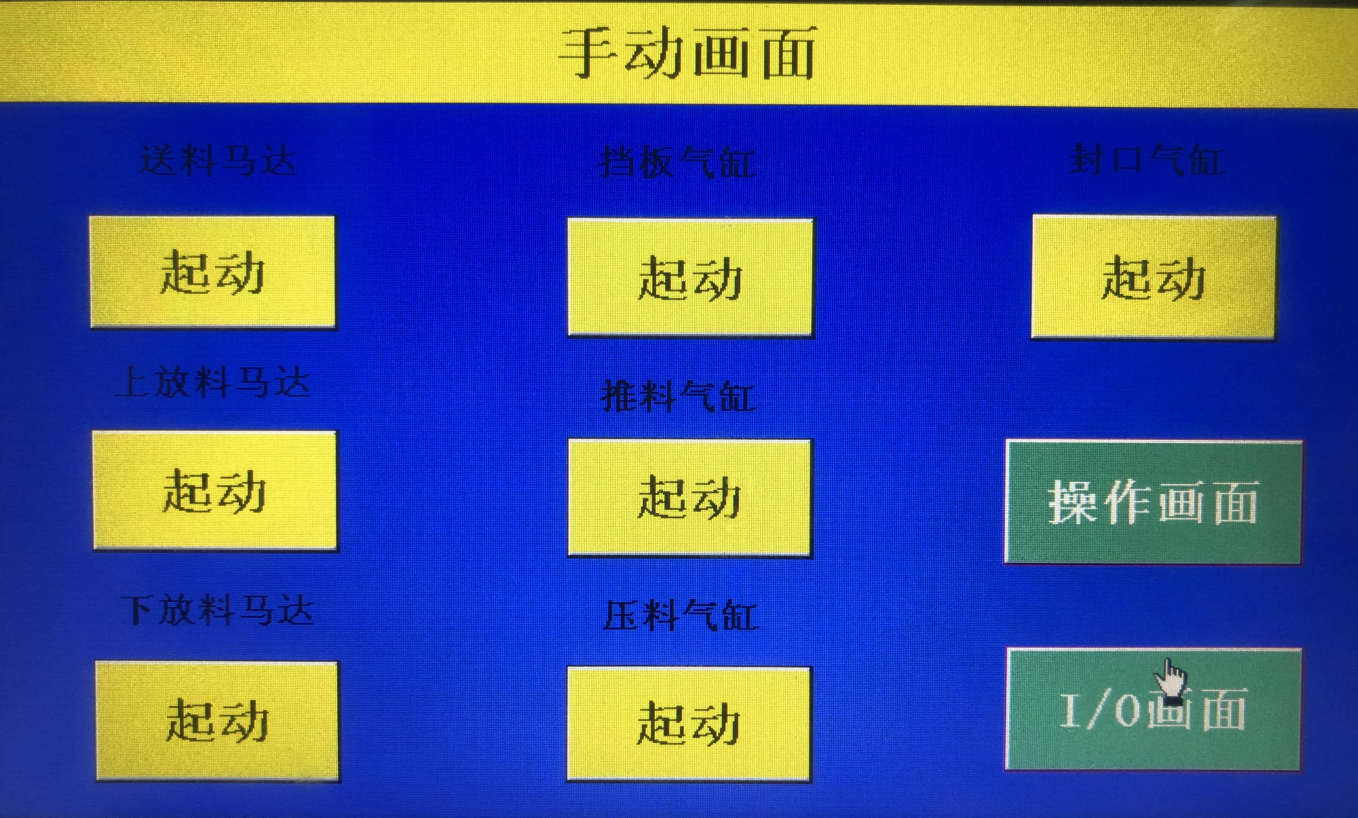

Manual mode: press the manual screen key to enter the manual screen. Each action has corresponding independent operation key, which is used for machine adjustment and maintenance

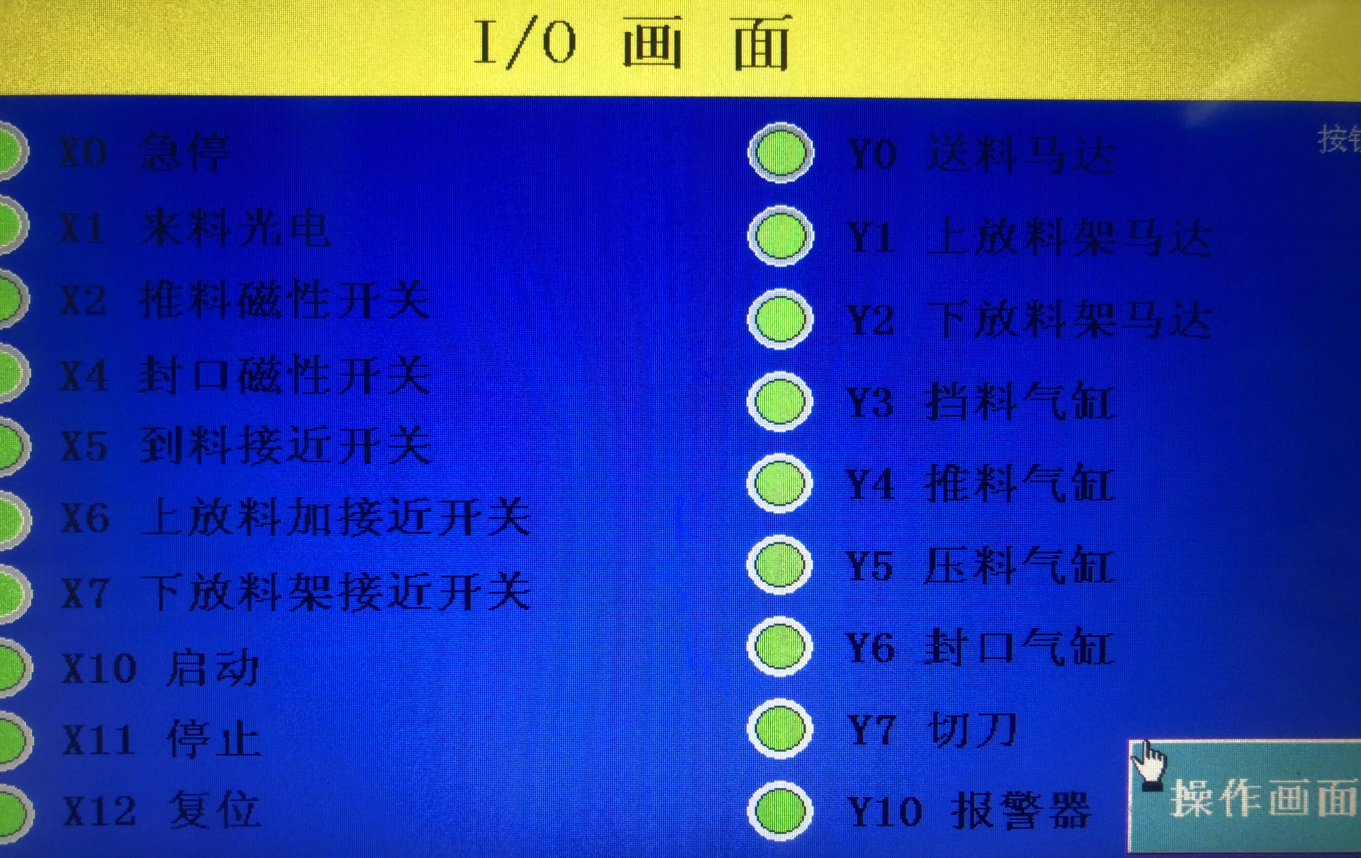

11: I / O screen: This screen is the connection number description of programmer's external control. It is used for maintenance

Seal cutter description

The sealing cutter is cold sealing, no temperature, no blade, controlled by pulse producer.

1: The lower knife is made of silica gel pad, and then pasted with high temperature resistant Teflon tape. The upper knife is made of special sealing wire,

2: High temperature resistant Teflon tape is pasted on the tool holder and installed in the sealing wire room. Please check the loss regularly. If there is any damage, please replace it in time.

3: Before starting the sealing wire every day, touch the surface finish of the sealing wire by hand. If there is any foreign matter on it, please clean it in time. The surface finish of the sealing wire must be kept to ensure the sealing effect

4: Sealing wire for wear and tear products, random distribution, later can buy from our company.

5: For the installation of the sealing wire, install the two ends into the copper column hole, tighten the screw, and then tighten the screw at the two ends. The sealing wire must be tight, and the length of the sealing wire must not be too long, and the length must be just right. If the sealing wire is too loose, the sealing effect is not good, and the service life of the sealing wire is reduced.

How to maintain xq-500-a packaging machine?

Please form good maintenance habit when the equipment is in normal operation

1: Screw, screw and bearing, please clean regularly every month, add grease

2: Clean the dust regularly to ensure the service life of electrical components

3: Regularly check whether the screws of the machine are loose and lock them in time