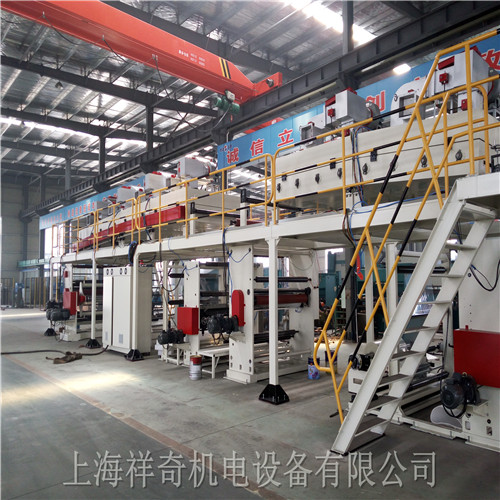

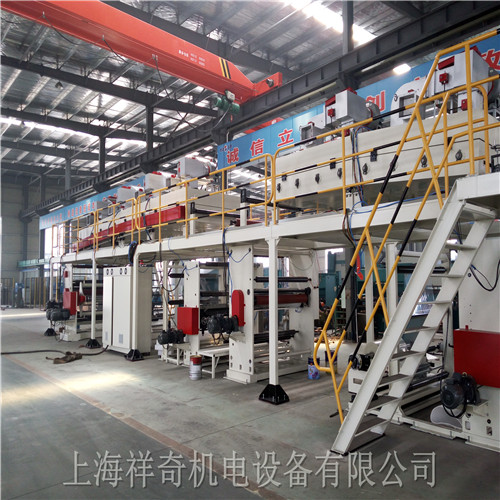

Working process of coater: apply a layer of glue, paint or ink on the rolled base materials, such as paper, cloth, leather, aluminum foil, plastic film, etc., and dry them before winding.

Coater working principle of automatic coater: the working principle of automatic coater for screen printing plate making is the same, but its performance is different according to different models and different consumer manufacturers. The vertical frame of the screen coater is provided with an installation device which can clamp the screen frame. The front and back of the screen area is a coating mechanism, which is composed of a coating groove and mechanical or pneumatic parts that control the angle and pressure of the coating groove.

The two ends of the coating mechanism are installed on the vertical support arm of the coating machine. Through the transmission of belt, chain or cable, the coating mechanism moves up and down to coat along the outer surface of the screen. The driving mechanism is connected to the servo or frequency conversion motor to make its operation stable and accurately control the position of the coating mechanism.

Before coating, will clean, stretch the screen from the front of the coater, some models can also be loaded from the side screen. In the model designed for large format screen frame, side mounting is more common. Because the screen frame is large and bulky, side mounting can reduce the lifting and moving amount. When the automatic screen coater is connected with other automatic screen processing equipment (such as cleaning equipment, recycling equipment, dry installation and developer), it is more convenient to install the plate from the side.

No matter how the screen is installed, once the screen is in the correct position, the pneumatic clamping installation or mechanical clamping installation is closed to lock the screen. In order to operate more easily, many models have pedal control version clip action, operators can free their hands to control the screen. After the screen plate is installed, the corresponding photosensitive emulsion is poured into the automatic coater to start coating. According to the function of the control system and equipment, the equipment can stop coating on both sides of the screen at the same time.

There are two coating methods, one is after repeated wet pressure wet operation in the screen coating emulsion; or after each coating plus dry process. A machine for quantitatively coating liquid (or melt) polymer materials such as adhesives or coatings on the surface of materials.

It is suitable for the consumption of PVC / PE film and other soft base materials

Simply put, it is to apply glue to the film. Detailed including gelatinization, drying, winding and tension control.

Film can be PVC, PE, pet... Also can be some paper, such as re release paper coated with hot melt adhesive

In order to meet the packaging requirements of containerized storage, transportation and mechanized loading and unloading of goods, the coating machine has designed and manufactured a series of products, such as tray coating machine, top pressing anti pulling coating machine, pre pulling automatic film coating machine, which are widely used in the containerization cost of export, food and beverage, irrigation, papermaking, dyestuff, plastic chemical industry, glass ceramics, mechanical and Electrical Castings, etc It can not only improve the consumption efficiency, but also avoid the damage of goods in the process of transportation, and play the role of dust-proof, moisture-proof and cleaning.

The working principle of the coating machine is to place the wound object in the center of the turntable, start the turntable motor to rotate, and naturally drive the turntable to rotate, so that the object completes the peripheral winding machine. At the same time, the elevator motor also starts to drive the whole assembly of the winding and binding machine to move up and down to reach the winding direction of the object height, which completes the winding and packaging of the whole surface of the object. This is not only conducive to the packaging requirements of goods storage, transportation and mechanized loading and unloading operations, but also can avoid the damage of goods in the process of handling, play the role of dust prevention, moisture-proof and cleaning, reduce the consumption cost and improve the consumption efficiency. In the winding process, the main thing is to adjust the tension of the film and to wear the film. Generally, the film tension level can be reached by adjusting the rotating speed of rotary table and regulating the rotating speed of motor. Just know that the faster the turntable speed, the slower the motor rotation, the tighter the membrane will be, otherwise, the looser this principle is not difficult to operate.