The traditional coating machine can only use low solid content coating and low cost coating

The coater includes coating (feeding) and metering system, drying system and finishing system. Coating and metering system, known as coating head, also known as coater, is the heart of coater. The quality of coated paper is mainly determined here. The name of coater is usually named after the characteristics of coating head (such as measurement method). The improvement of coating equipment mainly refers to the improvement of coating head. There are many kinds of coaters. At present, the widely used coaters are air knife type, extrusion roller type, scraper type, scraper type, etc.

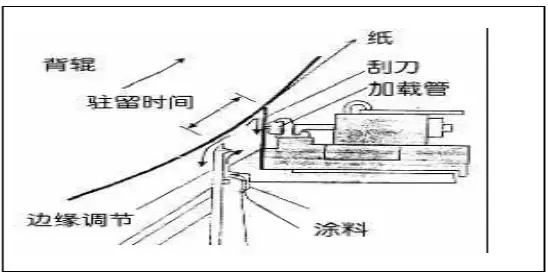

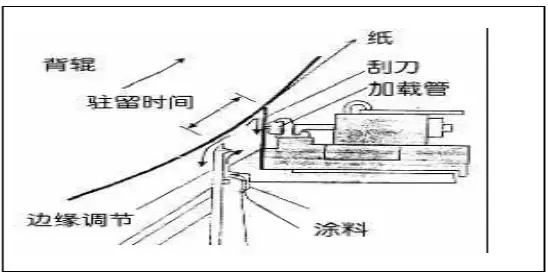

The coater equipped with the traditional coating head can only use low solid content coating and low speed coating due to the splash of material pool and the stability of coating amount. Generally, when the velocity is higher than 700m / min, the fluid in the material pool becomes very unstable due to mixing air and turbulence. When the residence time between coating application and measurement is long, the wet coating is easy to weaken the strength of the paper and cause end breakage. The purpose of the short dwell coater, which was developed in the later stage, was to apply low strength base paper on the high speed coater at that time and reduce paper breakage.

The coating enters the coating chamber through the orifice at the bottom of the coating chamber through the distribution system, and then the fresh coating enters a vortex body to mix with the coating that has been in the chamber. The material balance in the chamber is maintained by flowing to the return gap. It is also critical for the reflow coating to escape air from the sealed short dwell coating chamber, because a large amount of boundary layer air is entrained on the surface of the web during high speed coating. Between the reflow gap and the scraper, the coating is accelerated close to the surface of the paper, and the excess coating is scraped away by the metering scraper, only the required coating amount is retained on the paper surface.

The typical dwell distance between the reflow gap of the short dwell coating device and the metering scraper is 30-50 mm, which is less than 1 / 10 compared with the typical dwell distance of 600 mm of the roller feeding device. In a coater running at 1000-1500m / min, this is equivalent to a dwell time of only 1.2-1.3ms. This is the only important factor that results in less moisture gain and less strength loss of base paper.

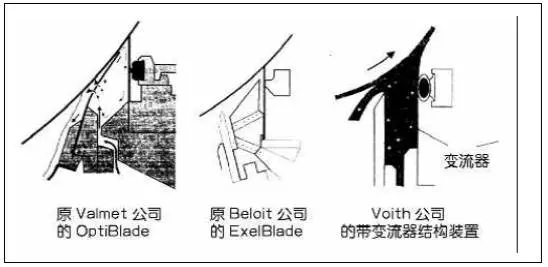

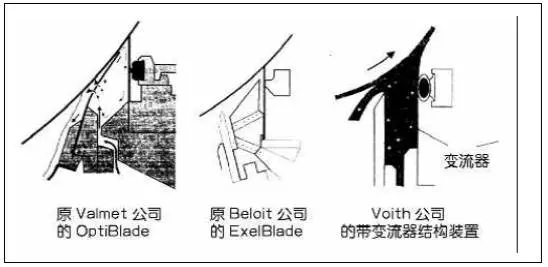

But the short dwell coating head in higher speed coater, easy to appear a kind of called "short dwell stripe" (often in high coating, low blade load) phenomenon. This kind of random short persistent stripe with a width of 5-30mm and a length of 100 mm or even several meters is considered to be the main quality defect of high-speed coater in 1980s.