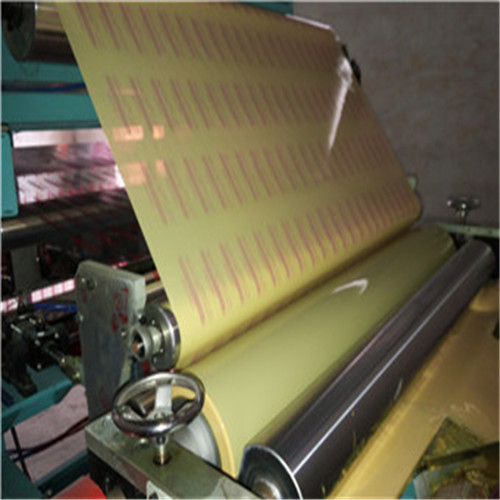

XQ-500 precision coating belt machine can produce transparent sealing tape, color printing tape, yellow tape, etc.

[matching] automatic pipe cutting machine and automatic pipe loading and unloading machine shall be provided during use

[purpose and characteristics]

·It can cut paper tube with inner diameter of 76mm and length of 50mm.

·Using air pressure tension, cutting speed, reasonable structure, simple operation.

·Cutting width can be adjusted arbitrarily.

Technical parameters of XQ-500 precision coating belt machine:

Machine type: oven heating type, strong arch type,

Base material width: min500-max.1600mm

Coating width: 500mm -- 1650mm

Base material diameter: max. 800mm

Coating: water glue

Length of base material: 500-6000m. (the outer diameter is 800mm.)

Gluing method: scraper type gluing

Glue viscosity: 50-150cps

Mechanical speed: 30-200 M / min

Coater speed: 30 ~ 200m / min (according to customer requirements)

Reference temperature: indoor: calculated according to min.10 degree C

Oven temperature: up to 130 ℃

Heating mode: electricity, steam, heat transfer oil (according to customer's choice)

Coil unloading mode: double station exchange coil unloading

Coiling mode: double station exchange coiling

Compressed air: 5kg / cm2

Main engine power: 3-phase, 380V, 50 Hz

Application scope:

This belt conveyor is a kind of machine which can complete the process from film to finished belt in one time. At the same time, this machine can also print advertising words, trademark patterns and so on according to the needs of customers. The cutting width and length of the tape can also be adjusted on this machine. This equipment can produce transparent tape, opaque tape, printing tape or similar products.

Tape material:

1. BOPP film 2. Water based pressure sensitive adhesive 3. Paper tube

Equipment features:

1) Excellent performance

1. High degree of automation: the equipment adopts electronic temperature control, stepless speed regulation, re air circulation, automatic counting, intaglio two-color printing, rewinding and other high-tech. Set printing, gluing, drying, slitting, winding and other production processes completed by one machine. The operation is simple and only 1-2 workers are needed for production.

2. Many specifications: the main structure of the belt conveyor produced by our factory is divided into two types: 500 type and 1000 type. There are electricity, coal, liquefied gas, steam and so on. There are dozens of series of varieties to meet your different choices.

3. Environmental protection and energy saving: superconducting re air furnace is adopted, which has high re efficiency and fast re transmission. The exhaust gas is equipped with a filter device, which is sanitary and convenient, and has no environmental pollution.

4. One machine with multiple functions: This machine can not only produce conventional self-adhesive tape, but also produce various kinds of wide tape, narrow tape, transparent tape, color tape, printing tape (three different color effects can be printed at the same time), etc

2) Advanced technology

Power part: adopt double power and double frequency converter for speed regulation, and the power of the equipment runs more smoothly

Printing part: monochrome intaglio printing.

Gluing part: automatic gluing is adopted. The thickness of glue can be adjusted according to customers' requirements, and the thickness of coating can be adjusted automatically and manually.

Drying part: using double drying channel drying, at the same time with the mainstream fan for re air circulation

Temperature part: adopt subsection temperature control!

Slitting part: 2-axis automatic slitting. At the same time, it has the function of winding up

Correction part: high sensitivity infrared correction is adopted

Finished tape:

Equipment production site:

Delivery site:

After-sale service:

After sales service: in order to create collage, improve popularity and set up image, we solemnly promise to you in the spirit of "all pursuit of high quality, customer satisfaction" and the principle of "appropriate price, considerate service and reliable quality":

1、 Quality commitment:

1. The manufacturing and testing of products have quality records and testing data.

2. For the testing of product performance, we sincerely invite users to check the process and performance of the product in person, and then pack and deliver the product after it is confirmed to be qualified.

2、 Product price commitment:

1, in order to ensure the high reliability and advanced nature of the products, the well-known products are selected for the system.

2. Under the same conditions, on the basis of not reducing the technical performance of the product and changing the parts of the product, I sincerely provide you with the right price.

3、 Delivery commitment:

1. Product delivery time: according to the user's requirements as far as possible. If there are special requirements and it needs to be completed in advance, the production and installation can be specially organized to meet the user's needs.

2. When the product is delivered, I will provide the following documents to the user;

① Technical maintenance manual

② General installation drawing

③ Specification and manufacturer of purchased parts

④ Provide the list of wearing parts and spare parts, and attach a certain amount of spare parts

4、 After sales service commitment:

1. Service tenet: fast, decisive, accurate, thoughtful and thorough

2. Service goal: win customer satisfaction with service quality

3. Service efficiency: if the equipment fails during or outside the warranty period, the supplier can reach the site and start maintenance within 24 hours after receiving the notice.

4. Service principle: the warranty period of the product is 24 months. During the warranty period, the supplier will repair and replace the parts and components damaged due to quality reasons free of charge. For the parts and components damaged beyond the warranty period, only the cost is charged. For the equipment damage caused by the demander's human factors, the parts and components repaired or provided by the supplier are calculated at the cost price.

Outside the warranty period, our technical personnel will visit the users at least three times a year to investigate their usage.

Enterprise website: www.xrtubuji.com

Contact person: Manager LV

Q Q: 2584385942

Mobile: 13761127036

Address: 1292 Waiqian Road, Jiading District, Shanghai